A new standard for plant-based bioproduction

Redefining how plant actives are produced

Plant-derived compounds have long been at the core of therapeutic and cosmetic innovation. Yet conventional sourcing methods, from field cultivation to solvent extraction, remain slow, variable and resource-intensive, which limits both reliability and scalability.

SATIVITRO® was developed to overcome these limitations.

By combining plant metabolic engineering with root-based bioproduction, our platform delivers rare bioactive molecules with high biosynthetic precision, batch-to-batch reproducibility and a markedly reduced environmental footprint.

The roots of scalable bioproduction

At the heart of SATIVITRO® lies a unique biological system : hairy roots.

These fast-growing plant root tissues are generated through a natural transformation process using Rhizobium rhizogenes.

They combine the advantages of in vitro culture with the full metabolic capacity of the plant, making them uniquely suited to the production of rare, complex natural compounds.

What sets our platform apart is not only its ability to reproduce nature’s biosynthetic complexity, but to do so with the standards of modern biomanufacturing : reproducibility, scalability and traceability.

Sustained growth

Once established, cultures grow vigorously in vitro without external hormones.

High biosynthetic fidelity

Hairy roots synthesize the same complex metabolites as the parent plant.

Engineering-ready

Their genetic makeup can be enhanced to boost productivity and direct biosynthetic pathways.

Stability & reproducibility

Genetic and biochemical traits remain stable over time, ensuring consistent production.

A new generation of plant bioproduction

SATIVITRO® combines plant metabolic engineering with a proprietary root-based bioproduction system, designed to replicate the biosynthetic power of plants in a clean and fully controlled environment. Within this system, advanced molecular tools can fine-tune metabolic pathways, unlocking higher productivity and optimized biosynthetic performance.

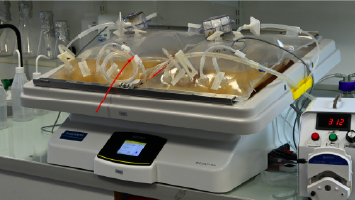

Instead of depending on land, climate or harvest cycles, we cultivate optimized root systems in sterile bioreactors. Every stage of the process is monitored and standardized, ensuring full control over quality, yield and traceability. This also allows SATIVITRO® to scale seamlessly, from research batches to larger bioreactors, while maintaining consistent performance over time.

From next-generation therapeutics to high-performance cosmetic actives, SATIVITRO® provides a smarter and more sustainable way to access the power of nature.

How SATIVITRO® works

Our technology follows a three-step process that transforms plant material into a reliable source of high-value bioactives :

1. Root induction

Using Rhizobium rhizogenes, we initiate root cultures from plant tissue – creating a stable and renewable production system, independent of soil or climate.

2. Metabolic engineering

With advanced molecular biology tools, we optimize key pathways to boost productivity and enhance the yield of target compounds.

3. Scalable production

Optimized root lines are transferred into controlled bioreactors, enabling seamless scale-up from research batches to industrial production.